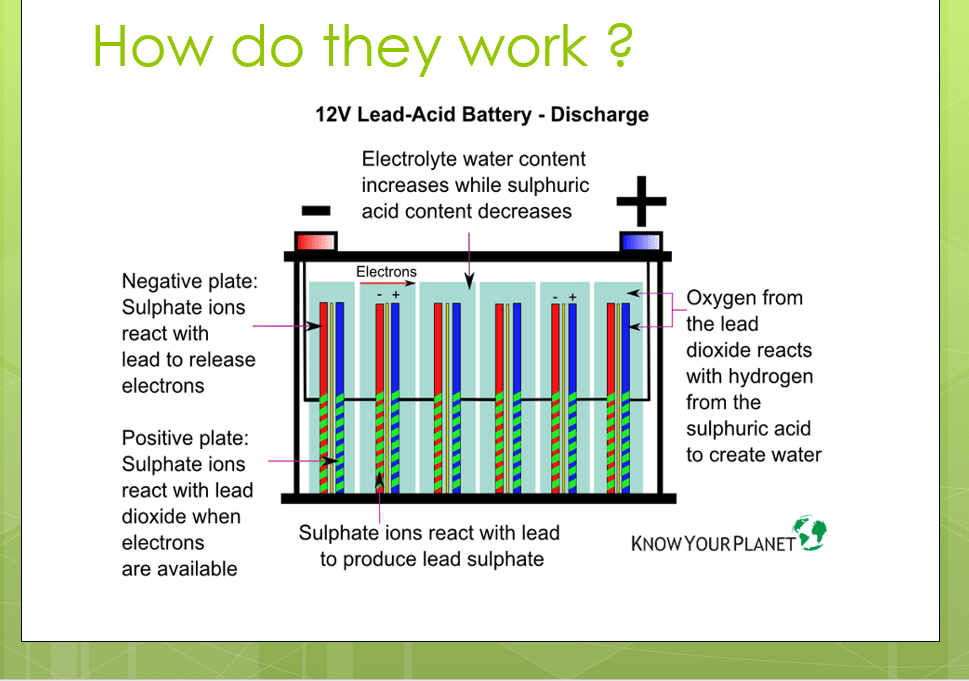

What is a Solar Tubular battery? Is it a battery made for Solar purposes? We will discuss this topic in this article. A solar tubular battery is a lead-acid battery specifically designed with a C10 rating. It has more capacity than a C20 battery, which is generally used for the Inverter/UPS application. It is characterized by its tubular-shaped cells, which comprise a series of lead plates separated by separators and immersed in an electrolyte solution.https://suvastika.com/difference-between-c20-and-c10-tubular-battery/

Solar tubular batteries were launched by making them C10 battery, which means it has more capacity than C20 battery, which is not very helpful in a solar battery. Most people were told that Solar batteries could take more charging current as it’s a C10 battery, and the dealers and resellers believed the same theory. The Solar battery is no different from the ordinary Tubular battery except it has a little more capacity, so if we take the example of a 150 Ah tubular battery, the solar battery with a C10 rating will have 170 Ah capacity. So in technical terms, there is hardly any difference as it will give slightly more backup.https://medium.com/@alphazee17/what-is-the-difference-between-a-solar-battery-and-a-tubular-battery-872140135ec4

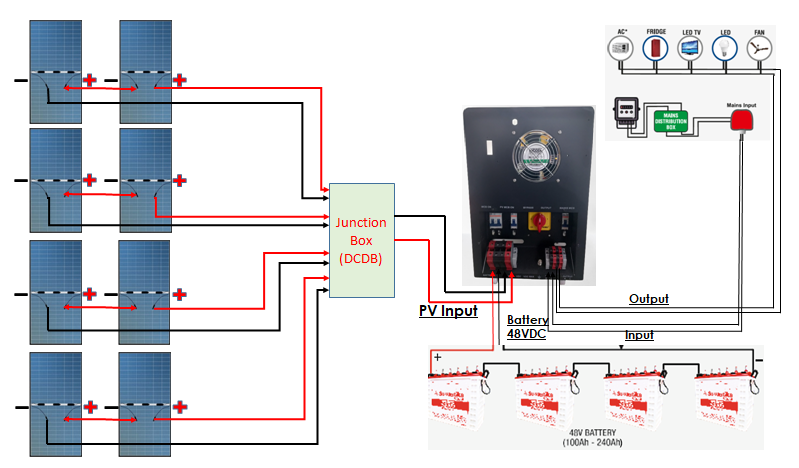

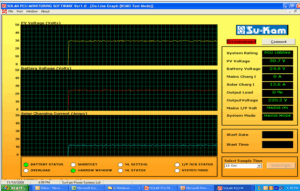

In India, companies started making Solar PCU with higher capacity solar charge controllers like 40Amp and 50 Amps and 60 Amps so that users can install more solar panels with a smaller battery bank. Solar charge controllers of such high capacity in the Solar PCU are a very dangerous trend as these charge controllers are destroying the life of batteries, and many battery blasts are taking place because the batteries are charged at a very high rate of charge. The Tubular Lead Acid battery will be charged at 10% of its capacity, so a 150 Ah Tubular battery can be charged only with a 15 Amps charging current. Still, nowadays, most branded companies are making solar PCUs with charging currents of 50 and 60 Amps which are becoming the cause of battery explosions. The battery needs water topping every month as the heat is created inside the battery when the battery is charged with such a high current.

solar panels

On the other hand, companies are telling the customer that the Solar charge current is shared between the load and the battery charging. This is another lie the companies are making fools of people when the grid is available. There can’t be any charge sharing between the Load and battery charging. It can only happen when the grid is not available.

In the Solar PCU, which are made in India, they keep charging the battery through the Solar Charge controller, and when the battery is fully charged than they cut the gid power and run the load, which is a very old technology adopted by the manufacturers and the battery life is restricted as the battery is charged and then discharged in each cycle. So Tubular battery, which can last for 500 to 600 cycles if charged properly, cannot perform in the Solar PCU system. There are a lot of complaints within two years of functioning, and the culprit is Solar PCU designed for higher charging current to install more panels. Generally, the dealer tells the customer to install 1000-watt solar panels with a 2 KW solar PCU with two Tubular batteries, so 2KW has a 24 V battery system. In this system, the batteries are charged with almost a 40 Amp charging current, creating many problems for the user. Also, people who install the Solar PCU complain their electricity bill has increased rather than reduced as people installing the solar PCU think that their electricity bill will reduce after installing the solar system. Still, the Solar PCU increases the electricity bill rather than reducing it.

Solar PCU is successful with tubular batteries as an off-grid system with no grid available, or a grid is available for much less time, so in that case, the solar is properly utilized.

In the areas where the Grid is available, and power cuts are not for a longer period, the solar PCU is a failure concept as it increases the power bill and reduces the Tubular battery life.

Now the real solution is a Lithium battery for the solar PCU systems as this can charge the battery faster as Lithium has the C/2 charging capacity, or we can charge the lithium battery at 50% of its rating in comparison to 10% of its capacity in case of Tubular Lead Acid batteries. The life span of Lithium compare to the Tubular battery is also four times, so this is the ideal solution to install with the Solar PCU.https://suvastika.com/tubular-battery-is-c20-and-c10-and-lithium-battery-is-c1-capacity/