Here are a few reasons why India is becoming a hub for exports in the inverter industry:

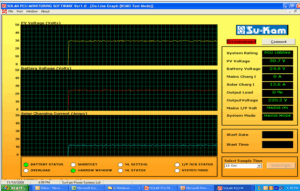

Mr. Kunwer Sachdev, the founder of Su-kam, known as the Inverter Man of India, was the first person to export inverters from India.

He was instrumental in creating the latest technologies in the Inverter Industry in India.

People working with him started their own companies to create export from India, and slowly, the movement took a solid shape.

India’s brand in export is built in Africa, the Middle East, South America and South East Asia.

Cost-effective manufacturing: India has a large pool of skilled Labour and a well-developed manufacturing infrastructure, which makes it a cost-effective place to manufacture inverters.

Access to raw materials: India has access to a wide range of raw materials used in inverter manufacturing, such as silicon, copper, and aluminum. This gives Indian manufacturers a competitive edge over their counterparts in other countries.

Government support: The Indian government has supported the inverter industry, providing subsidies and tax breaks to manufacturers. This has helped to attract investment in the sector and boost exports.

Growing demand: The demand for inverters is increasing in India and worldwide as more and more people use solar power and other renewable energy sources. This is creating new opportunities for Indian inverter manufacturers to export their products.

As a result of these factors, India is now the second-largest exporter of inverters in the world after China. The industry is expected to grow in the coming years, making India an even more important player in the global inverter market.

Here are some additional details about the Indian inverter industry:

The Indian inverter market is estimated to be worth around $2 billion.

The market is growing at a CAGR of approximately 10%.

The major players in the Indian inverter market include Su-vastika, Luminous, Microtek,Su-mak and Livguard

The main export destinations for Indian inverters are the United States, Europe, and Africa.

The Indian government is working to promote the export of inverters by providing subsidies and tax breaks to manufacturers.

Overall, the Indian inverter industry is well-positioned for growth in the coming years. The country has many advantages, such as cost-effective manufacturing, access to raw materials, and government support. As a result, India is becoming a central hub for exports in the inverter industry.