The important parameters of a lithium cell are:

- Nominal voltage: The nominal voltage is the average voltage of the cell when it is fully charged and discharged. For most lithium-ion cells, the nominal voltage is 3.2 or 3.7 volts, depending upon the lithium cell chemistry.

- Capacity: The capacity is the amount of energy the cell can store. It is measured in milliampere-hours (mAh) or Ampere-hours (Ah). It’s in mAh for smaller cells, and bigger lithium cells, it’s in Ah called Ampere Hour.

- Energy density: The energy density is the amount of energy the cell can store per unit mass or volume. It is measured in watt-hours. This energy can be converted into simple wattage terms by multiplying the cell voltage with the cell capacity. say 3.2 volts multiplied by 100 Ah if the cell has 100 Ah, which comes to 320 Watt capacity.

prismatic cell Lithium pack

- Power density: The power density is the amount of power the cell can deliver per unit mass or volume. It is measured in watts per kilogram (W/kg) or per litre (W/L). So if the 100 Ah cell is 3.2 Volts, then what is the weight of the 320 Watt cell? And that can be converted into the per-watt weight and cell size.

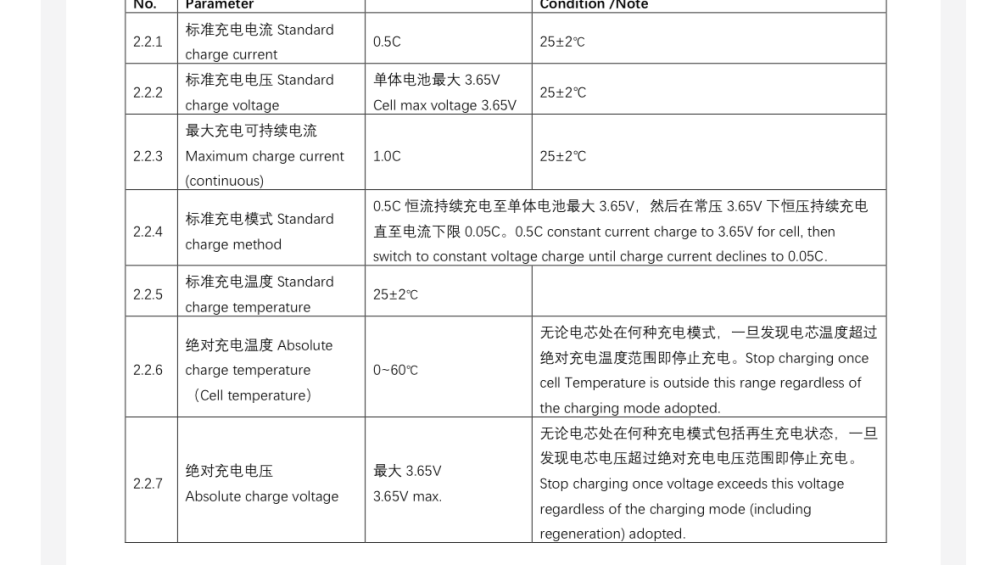

- Charge rate: The charge and discharge rate is the rate at which the cell can be charged and discharged. These two are very important to understand as the manufacturer specifies the maximum charge rate in terms of the total capacity of the lithium battery cell. Say a 100 Ah cell has a 0.5 charge rate, so one has to understand that the maximum charge we can give is 50% of the capacity of a lithium cell so that we can charge the cell with a 50 Amp charging current.

- Discharge Rate: This is defined as the nominal or maximum discharge current we can discharge from the Lithium cell, so it’s defined in terms of 1C or 0.5C, 2C or 3C, which means we can discharge the maximum cell current in that capacity only, say 0.5C means we can discharge 50 Amps in one hour from the 100 Ah capacity lithium cell or 1C means 100 Amp we can discharge in 1 hour and so on. This is very important to understand while reading the specifications of the lithium cell.

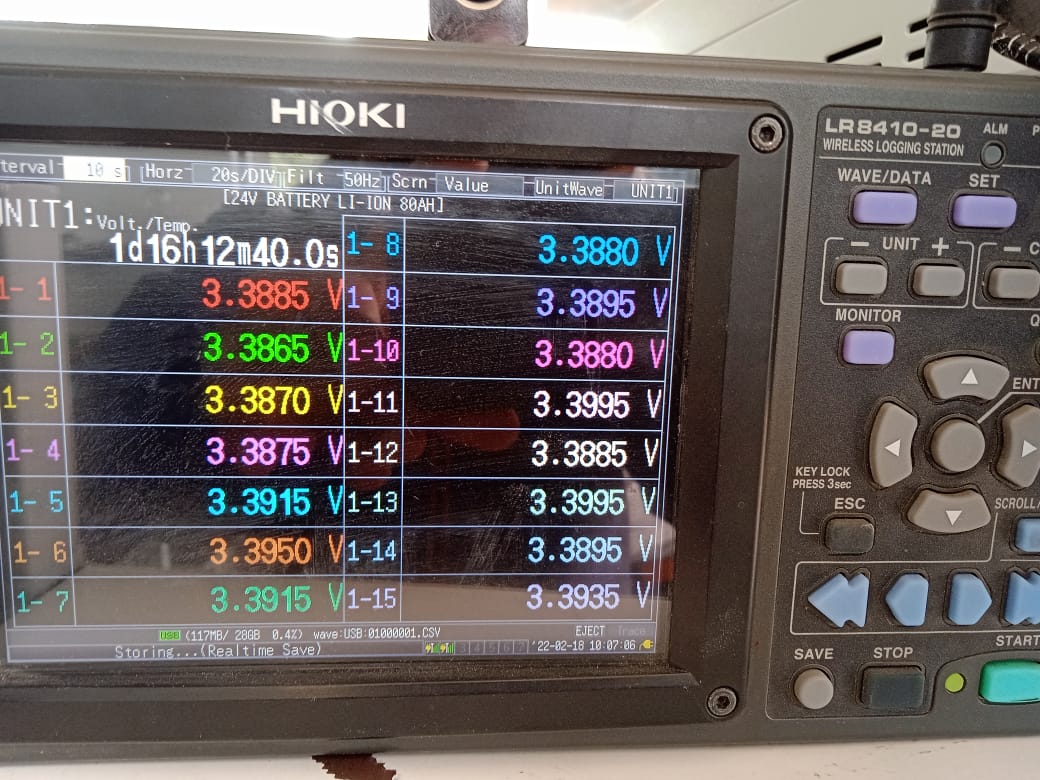

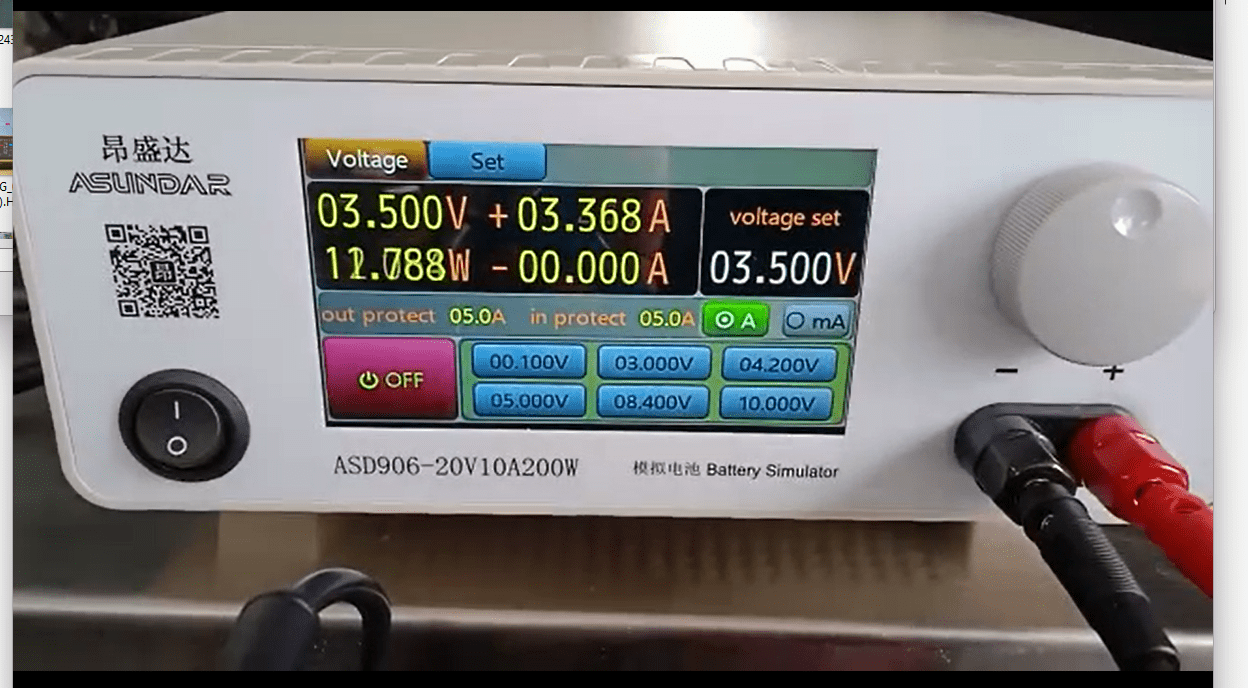

- Internal resistance: The internal resistance is the cell’s resistance to the current flow. It is measured in ohms. So, generally, internal resistance plays an important role while grouping the cells to make the lithium cell pack. When we charge or discharge them in a battery pack, we can get the cell equalization in voltage under check. If the two cells have different internal resistance, the battery will give less life, and one of the cells might get overcharged over time. The cell IR is generally in milli Ohms, and the IR will increase from the time of cell cycle life. So, we measure two types of IR: the Lithium cell IR value and the Lithium cell pack IR value, which indicates the health of the Lithium cell and Lithium battery pack. As the battery pack goes old after use of maybe three years, one can see the increase in IR value of the total cell pack, which will increase in milli ohm, indicating the battery pack life left.

IR testing

- Self-discharge rate: The self-discharge rate is when the cell is not in use, neither it’s charged nor discharged. Also, the cell is losing some charge, called the self-discharge rate. Lowering the self-discharge improves the battery cell life as every battery cell has its self-discharge rate at which it will be discharged when not in use. When the lithium cell is made and despatched, reaching the destination takes a lot of time. Then, the cell is stored at a particular temperature, which is generally supposed to be 25 degrees Celsius. So, a better life can be expected by lowering the self-discharge rate of any lithium cell. Every manufacturer specifies the self-discharge rate at a standard 25 degrees Celsius.

- Cycle life: The cycle life is the number of times the cell can be fully charged and discharged before it reaches a specified capacity level. This denotes the life of a battery, as more cycles mean it has a better life. Generally, the cylindrical cells of LifePo4 of 6 Ah capacity have 2000 cycles, and it has a lot of riders, like the charging rate, discharging rate and the temperature at which it’s kept, etc. So, the cycle life can increase or decrease depending on the variables.https://en.wikipedia.org/wiki/Lithium_iron_phosphate#:~:text=Lithium%20iron%20phosphate%20or%20lithium%20ferro-phosphate%20%28LFP%29%20is,iron%20phosphate%20batteries%2C%20a%20type%20of%20Li-ion%20battery.

- Operating temperature range: The operating temperature range is the range of temperatures at which the cell can operate without damage, and the life can increase or decrease if the temperature varies. The cell’s capacity will also vary depending on the temperature range specified by the manufacturer.https://suvastika.com/the-lithium-battery-is-going-to-change-the-energy-storage-solutions/

These are just some of the important parameters of a lithium cell. Other parameters may be important depending on the specific application of the cell.