What is an Inbuilt Lithium battery Energy Storage System? How it’s different from the normal inbuilt battery UPS or stand-by UPS? Understanding how Battery Energy Storage differs from the normal in-built UPS is important. The normal UPS is an Uninterruptible Power Supply which everyone understands is the Power Supply used to power IT loads like Computers, printers, cameras etc., in case of power outages or power fails as well; it takes care of Voltage fluctuations when the main power is coming. The UPS has an inbuilt Lead Acid SMF battery that works without any switch over time or transfer time, so in case of power failure, the computers, printers etc, keep working without any interruption. These UPSs are available in the market with a built-in lead acid battery that works for two years, and then, one has to replace the battery every one to two years as the life cycle of a Lead Acid SMF battery is not more than two years. Another challenge is that the in-built UPS battery generally has a very limited backup time; it’s for 15 minutes only. These in-built UPS can only run IT loads as the IT reseller will not take any guarantee if someone tries to run fans or Light load on it, as they are not made for other types of loads.https://en.wikipedia.org/wiki/Uninterruptible_power_supply.

In-built SMF Lead Acid battery UPS

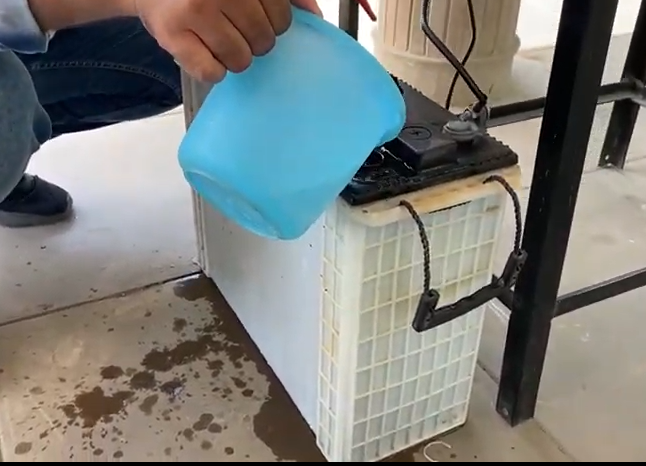

Lithium battery Inbuilt BESS

Su-vastika has launched An built Lithium Energy Storage System, which solves all UPS’s problems, like limited time and life and works only for IT Loads. So let us talk about the Inbuilt Lithium Battery Energy Storage Systems in length:

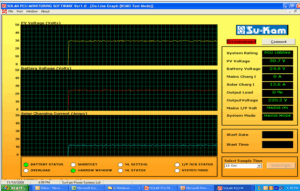

- The Lithium in-built BESS has the IOT feature to run on devices like Bluetooth and Wi-Fi. One can see the parameters of the BESS, like voltage frequency, load battery percentage etc., and control the BESS by settings the parameters and switching the load on and off remotely.

- The one important feature that makes it future-ready is the programming for the Peak Power tariff-ready BESS, which can control the power storage and usage per peak power timing. One can program the timing for charging through the Wi-FI-based application and set the Peak timings in the BESS so that BESS will switch off the Mains power and work on the Lithium battery when the user programs the peak power timings. This will reduce the power bill of the user in the peak timing. As all developed countries have this concept of peak power Tariff and normal power tariff in place, the developed countries are slowly bringing this concept. India has already announced peak power tariffs in the residential sector. The peak power tariff is in operation in India’s commercial sector already. The built-in Lithium battery size is 1/4th the size of an SMF Lead Acid battery and 1/4th the weight of a lead Acid SMF battery. The battery density in the SMF is higher compared to Lithium batteries. Because of this, the weight and size of the Lithium battery is reduced drastically.https://suvastika.com/lithium-inverter-lithium-ups-lithium-battery-for-home-and-office-back-up/

- The Backup time: normal in-built UPS can work for 15 to 30 minutes whereas our models can work from 1 hour back up time to 3 hours or more back up time.

- The Inbuilt UPS is good for the IT load only, whereas the Inbuilt Lithium BESS can work on any load like motor load or run Airconditioners and fridges, along with the IT loads. It can run heavy loads, and the Inbuilt UPS is not meant for any heavy loads and can run only IT loads.https://suvastika.com/whats-battery-energy-storage-system/

- The Battery Life: Inbuilt Lithium battery Life is a minimum of ten years and can last for 12 years, and the Lead acid battery lasts only a maximum of 2 years.

- The price of UPS, having built SMF battery and the price of Lithium inbuit BESS, has a difference of 50%, but the life is five times the battery life of the same capacity.

- The Battery Capacity: The built-in SMF battery in UPS has a C20 battery, whereas the Lithium battery has a C1 capacity. Because of this, we need to use half the Lithium battery capacity compared to the SMF battery capacity.

- The Charging Time: SMF battery will charge in 10 hours minimum, whereas the Lithium battery will charge in 2 hours in Inbuilt Lithium BESS.

- The charger size in the Inbuilt UPS is very small as the SMF battery is of small size and needs to charge in 10 hours, whereas the Lithium battery capacity is higher and needs to charge in 2 hours, so it needs a fast charger of higher capacity.

- Maintenance is required in in-built lithium BESS, and SMF-based built UPS need to change the battery, and sometimes multiple SMF batteries need to equalize over six months. The Inbuilt lithium BESS has the BMS system to control the parameters of the Lithium battery.