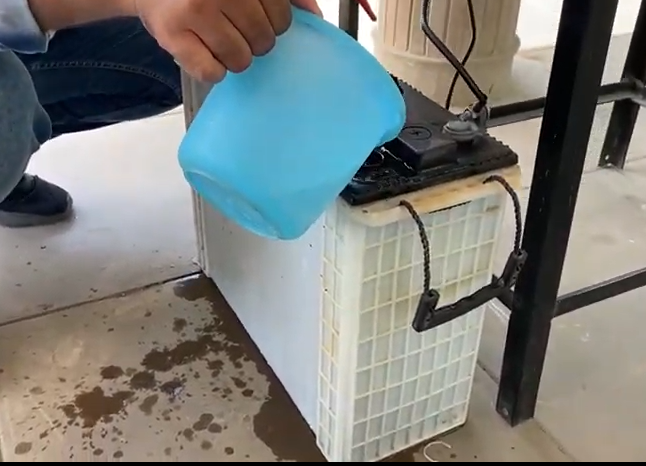

What are the Tubular Lead Acid Battery Health Hazards in Inverter/UPS Industry? People using Tubular Lead Acid batteries at homes and offices are not aware of the consequences regarding the health hazards of these Tubular Lead Acid batteries used in homes, offices, and other institutions.

When they charge and discharge, the Ttubular Lead-acid batteries create a lot of fumes which are healed knowingly and unknowingly by the people around them. World Health Organisation has been warning about the health hazards resulting from the pollution of Lead in different areas and is trying to create awareness regarding Lead poisoning. So I thought let me also make people aware regarding the risks of Tubular Lead Acid battery, which is being installed by the people inside their homes and offices, and no one knows how dangerous it can be when it spreads the lead fumes which are inhaled especially by the kids.https://suvastika.com/lithium-battery-is-going-to-replace-lead-acid-battery-technology/

Lead exposure can have serious consequences for the health of children. At high levels of exposure, Lead attacks the brain and central nervous system, causing coma, convulsions and even death. Children who survive severe lead poisoning may be left with intellectual disability and behavioural disorders. At lower levels of exposure that cause no obvious symptoms, Lead is now known to produce a spectrum of injury across multiple body systems. In particular, Lead can affect children’s brain development, resulting in reduced intelligence quotient (IQ), behavioural changes such as reduced attention span, increased antisocial behaviour, and reduced educational attainment. Lead exposure also causes anaemia, hypertension, renal impairment, immunotoxicity and toxicity to the reproductive organs. The neurological and behavioural effects of Lead are believed to be irreversible.https://www.who.int/news-room/fact-sheets/detail/lead-poisoning-and-health#:~:text=Exposure%20to%20lead-contaminated%20soil%20and%20dust%20resulting%20from,such%20as%20the%20brain%2C%20kidneys%2C%20liver%20and%20bones.

There is no known safe blood lead concentration; even blood lead concentrations as low as 3.5 µg/dL may be associated with decreased intelligence in children, behavioural difficulties and learning problems (1). As lead exposure increases, the range and severity of symptoms and effects also increase. Lead Acid battery health hazards in the different age groups of people using Inverter/UPS vary in different areas. The lead fumes from Tubular Lead Acid batteries in Inverter/UPS are causing a lot of health hazards.

Encouragingly, the successful phasing out of leaded gasoline in most countries and other lead control measures has significantly declined population-level blood lead concentrations. As of July 2021, leaded fuel for cars and lorries is no longer sold anywhere in the world (2). However, more needs to be done to phase out Lead paint; so far, only 45% of countries have introduced legally binding controls on Lead paint. Also ban on the Led Acid batteries being used for the Inverter/UPS, which are kept in the vicinity of homes and offices, is another form of Lead which is a major cause of concern for the various Govts. The major challenge is awareness of Lead as a deadly substance.

All dealers and distributors keep the Lead Acid batteries in the Air conditioned environments for selling purposes or sometimes keep the scrap in their shops and keep breathing the same lead fumes. They don’t realize the health hazards associated with this.https://www.sciencedirect.com/science/article/pii/S18780296160010

Environmental Concern about Tubular Lead Acid Battery Inverter/UPS

According to a 2003 report entitled “Getting the Lead Out” by Environmental Defense and the Ecology Center of Ann Arbor, Michigan, the batteries of vehicles on the road contained an estimated 2,600,000 metric tons (2,600,000 long tons; 2,900,000 short tons) of Lead. Some lead compounds are extremely toxic. Long-term exposure to even tiny amounts of these compounds can cause brain and kidney damage, hearing impairment, and learning problems in children.[34] The auto industry uses over 1,000,000 metric tons (980,000 long tons; 1,100,000 short tons) of Lead every year, with 90% going to conventional lead–acid vehicle batteries. While lead recycling is a well-established industry, more than 40,000 metric tons (39,000 long tons; 44,000 short tons) end up in landfills yearly. According to the federal Toxic Release Inventory, another 70,000 metric tons (69,000 long tons; 77,000 short tons) are released in the lead mining and manufacturing process.[35]

Attempts are being made to develop alternatives (particularly for automotive use) because of concerns about the environmental consequences of improper disposal and lead smelting operations, among other reasons. Alternatives are unlikely to displace them for applications such as engine starting or backup power systems since the batteries, although heavy, are low-cost.https://en.wikipedia.org/wiki/Lead%E2%80%93acid_battery

How does lead get in the Air?

Sources of lead emissions vary from one area to another. At the national level, major lead sources in the Air are ore and metals processing and piston-engine aircraft operating on leaded aviation fuel. Other sources are waste incinerators, utilities, and lead-acid battery manufacturers. The highest air concentrations of Lead are usually found near lead smelters. People using Inverter/UPS and installing Lead Acid batteries at homes, offices, schools, religious places etc.

As a result of EPA’s regulatory efforts, including removing Lead from motor vehicle gasoline, lead levels in the Air decreased by 98 per cent between 1980 and 2014.https://www.epa.gov/lead-air-pollution/basic-information-about-lead-air-pollution#how

An alternative to Lead Acid Tubular battery is the lithium battery

Nowadays, various types of Lithium batteries are available in the Inverter/UPS industry. Lithium battery is cheaper than the Tubular Lead Acid battery.